|

PRINCIPLE

OF FLUIDIZATION PRINCIPLE

OF FLUIDIZATION

When a bed of fine particles, for example sand, is

subjected to an upward stream of air, the particles

become suspended as the airflow reaches a certain

velocity. This condition is referred to as the minimum

fluidizing velocity and it varies according to the particle size

and the depth of the bed. When the bed is fluidized

it resembles a boiling liquid. Such a turbulent mass

of solid particles is named a fluidized bed. Coal

can be fed into the bed and as it burns it resembles

molten lava. If the gas velocity becomes too high,

then the particles are entrained in the gas stream

and are lost. A fluidized bed behaves like a liquid,

so both the bed level and temperature can be easily

controlled. Coal fuel enters the furnace slightly

above the fluid bed splash zone where the rising

stream of air and combustion gases burst from the

sand bed. The vigorous action of the bed causes the fuel to rapidly

mix and be quickly raised on temperature to its igniting point. Solid

fuel particles mixing with the rising air stream are jostled by the

hot bed material (sand, ash & fuel) causing rapid release of surface

moisture and volatile matter from within the fuel. The relatively

large mass of moving bed material continually exposes new surfaces

of the fuel particles for combustion, sustaining the rapid combustion

within the bed. The rapid combustion enables very good load response

to be maintained. (Closely approaches that of oil fuel) WHEN the

fluidized bed design is compared with conventional grate systems

the following specific capabilities of the former enable a practical

unattended control procedure (automatic controls) to be devised and

implemented;  Combustion

temperatures are significantly lower and thus much safer conditions

are continually maintained (well under 1000 °C ) Combustion

temperatures are significantly lower and thus much safer conditions

are continually maintained (well under 1000 °C )

The nature of a fluid bed ensures that mal-distribution is not likely

to occur. Fuel migration through the bed is fast and even. Air distribution

is insured by the designed configuration and location of the air nozzles.

The bed combustion can be stopped instantly by turning off the air

supply to the bed. This action results in the bed slumping, thereby

smothering combustion. The bed is inherently safe because it contains

only 3-5% combustible material as a maximum. This is evenly distributed

throughout the inert bed material. When slumped, the bed is safe and

permits an easy restart even after several hours simply by re-introducing

the airflow into the bed. This is possible because of the substantial

quantity of entrained heat in the bed material. The furnace is located

atop the air distribution plenum. It has an overall freeboard height

of about 5 meter. At its base, and assembly of In-bed tubes are positioned

so that at maximum steam output they are fully immersed in the expanded

fluidized bed. As the fluidizing air supply is decreased, the expanded

bed depth is reduced and the in-bed tubes are progressively uncovered

such that at all outputs approximately 50% of the heat release by combustion

is transferred to the in-bed tubes when burning coal fuel. This allows

a turndown of at least 3:1 at near constant excess air with the entire

bed in operation. Co-efficiency of heat transfer of the in-bed tubes

immersed in the sand bed is 5-6 times igher than that of the conventional

convection tube bank area. If design of boiler requires 30 m2 for convection

area to generate 1000 Kg of steam per hour, we can safely take 1/6

of it or 5 m2 to generate 1000 Kg of steam from the immersed in-bed

tube area.

The fluidizing air enters through air distributors mounted on a flat

base plate. The bed material is silica sand having a mean size of 0.9

mm (#3). Bed depth is about 400 mm.

START-UP BURNER

Start-up of the bed is achieved by the firing of an above bed distillate

burner, which is lit by Oil. Start-up is normally achieved in 45 minutes

from cold status. Hot starts normally are achieved in less than 10

minutes, 6 minutes of which is needed for purging to ensure there are

no pockets of ignitable gas in the boiler passes. If the bed temperature

is above 600 °C no oil fuel is needed to re-start the bed. Usually

bed can maintain enough heat or above 600 °C for 1-2 hours.

BED TEMPERATURE

The average bed temperature varies between 950 °C at full load to 750

°C at minimum load. In fluidised bed operation bed temperature is monitored

and is in fact a better indication of combustion condition than a flame

scanner used for oil burner.

FREE BOARD ZONE/ OVERFIRE 2ND AIR

The major proportion of the fuel is burnt within the bed, with the

remainder burning in the free board zone or disengaging space above

the bed. With the injection of overfire 2nd air into the free board

zone, disengaging space temperature will rise higher than the temperature

of the bed. The final gas temperature leaving the furnace will be similar

to the bed temperature as the elevation in temperature due to free

board combustion is partially offset by the heat transfer to the uncovered

portion of in-bed tubes and cooling effect of the fresh air injection.

COAL FEEDING SYSTEM

Fine coal is stored on the ground and normally flat conveyor system

transport coal from the in-ground hopper to the silo mounted at the

front of the boiler. The coal runs from the storage silo by gravity

to the screw conveyor with variable speed gear motor, then the coal

enters the furnace through an air swept spout.

SOOTBLOWERS

Soot blowers are not necessary to be installed as the combustion temperature

of the fluidized bed is controlled at well below the ash fusion temperature

and fly-ash entrained in the gases entering the convection tube banks

are dry and non-adhering and possess a self-cleaning action.

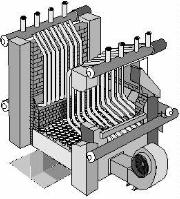

COASE ASH REMOVAL / CIRCULATING SAND BED SYSTEM COASE ASH REMOVAL / CIRCULATING SAND BED SYSTEM

Coarse ash

which is not elutriated from the bed must be removed. This material

is removed continuously by means of circulating sand bed. We call

this system as CIRCULATING BED. Air nozzles are screwed in to

the multiple air distribution pipes instead of base plate which

was used before. Because of this air distribution pipes, coarse

ash can fall below the pipe level travelling downward in between

the pipes and those materials will be discharged from the rotary

valve below together with the silica sand onto the vibrating screen

which will segregate those coarse ash and other foreign materials

from the pure silica sand. Then the pure silica sand will be returned

to the furnace through the sand returning pipe by blower.

CONTROL

a) Fluidized Bed Temperature Control

The bed temperature is controlled between approximately 750 - 950 °C

by varying the speed of the coal screw feeder in response to a signal

from the steam pressure and the bed temperature (2 factors)

b) Free

Board Draught Control

The draught in the free board is controlled at approximately

-50 Pa by adjusting the induced draught fan damper located after

the multi-cyclone dust collector.

c) Fluidized Bed Load Control

Under normal operating conditions, a manual set point forms

the load signal. This signal is used to adjust the fluidizing

fan damper. As the amount of air is varied to the furnace,

the coal feed rate will be regulated to maintain the bed

temperature. The fluidizing fan damper control is overridden

if the flow measurement indicates a fluidizing velocity

of less than 1 m/s.

d) Bed Level Control

Bed pressure is used to control the bed depth between an

effective static height of 120 mm to 180 mm. As the bed

pressure reaches the lower limit, the bed material is introduced

to the bed by starting the bed material feed screw.

ACID GAS EMISSION ( FBC, most

environmentally friendly system)

One of the main advantages of the fluidized bed boiler is

the fact that

the temperature spread in the furnace is small due to solid

mobility in the fluidized state. This feature is commonly

exploited for sulphur capture using limestone;

CaCO3 CaO + CO2

2CaO + 2SO2 + O2 2CaSO4

The thermodynamic stability of the sulphur capture product

declines sharply as temperature is increased above 900 °C

and for this reason, bed temperature is maintained between

800 - 900 °C . Ca/S molar feed ratio of around 2 - 2.5 are

typically used and sulphur capture efficiency for this type

of system is usually in the range 70-90 percent, depending

on limestone reactivity. Soft, dolomitic limestones are generally

the most effective for this service. In an overall sense,

FBC acid gas emissions are dramatically lower than those

from other combustion system such as chain grate stoker,

underfeed stoker, pulverized coal spreader etc.,( without

external flue gas treatment). Emission limits of (typically)

200-300 ppm for Sox and 100-150 ppm for Nox can usually be

met without resorting to post treatment of flue gas. ASH

/ CARBON / SAND / LIMESTONE The carbon content of the bed

is typically around 2-3 percent (as coal being 5% of the

total bed material) and the balance of the bed meterial can

be ash, sulphated limestone or sand. The preferred mode of

operation is one in which ash and limestone make up the bed.

In some instances limestone is not needed and ash content

is too low and friable enough to break down to fine particle

and be carried out of the bed. This case is specially with

the "ADARO COAL" of Kalimantan, Indonesia, which

contains only 1 % ash and 0.1 % sulphur. In such cases it is necessary

to add a material such as sand to the bed to maintain a suitable inventory

in the system. The performance of a particular coal in relation to

bed ash formation can be highly significant from a fuel selection point

of view - a boiler operator may not wish to add sand/limestone purely

for maintenance of a suitable bed. In such cases the supplier of a

coal which does not have good bed-forming properties may need to "spike" the

fuel with bed-forming agents. Ash softening temperature is an important

parameter. The fluidized bed must operate in a "Dry" condition since

any stickiness has the potential to cause uncontrolled agglomeration

and ultimately de-fluidization. Relatively few coals can produce

sufficient stickiness below about 900 °C to upset fluidization, though

coals which contain appreciable amounts of chlorine and/or alkali

metals such as Na and K are known to give problems.

ONLY FLUIDIZED BED SYSTEM CAN OPERATE JUST LIKE OIL/GAS BURNER

(Turn-down ratio 1/4)

Generation of heat can be adjusted freely up to the turn-down

ratio of about 1/4 by controlling coal fuel feeding and forced

fan damper openig to the minimum fluidizing velocity. At

the minimum fluidizing velocity, sand bed is still fluidizing

and continue to generate steam at 1/4 capacity. Between this

range of evaporation, Fluidized Bed can react most likely

to the Oil/Gas burner among any conventional coal firing

system such as chain grate and/or underfeed stoker.

NO LOSS OF REMAINING FUEL WHEN SHUT DOWN YOUR BOILER

Not like with the other systems, you do not waste any remaining

coal fuel when you want to stop the boiler. Remaining coal

still inside the sand bed when you turn off the air supply

to the bed shall have no more Oxygen supply and trapped inside

the hot sand without wasting carbon for no use. For any other

coal fire system like chain grate, all coal fuel already

stay on top of the moving chain grate shall have to finish

buring even the boiler stop operating and you do not want

steam any more. Those loss will count greatly in a long time

when comparing Fluidized Bed and Chain Grate.

NO CLINKER, NO ASH FOULING/SLUGGING

All ash will go out of Fluidizing Sand bed in a very dry

condition under low temperature of about 900 °C . This condition

of ash will never make problems of clinkering and never stick

on the surface of boiler tubes. Therefore, soot blower is

not needed for Fluidized Bed as mentioned previously. Only

fine and dry ash are collected by the multi-cyclone system

aftr the boiler and to be discharged through the rotary valve.

Since the quality of ash coming out from Fluidized Bed is

very fine and equal in its size, ash from the Fluidized Bed

Boiler will find commercial value for fertilizer, mixing

agent for cement moulded product, construction material,

filler for road making etc. Ash from other coal firing system

such as chain grate are very rough/coarse due to its high

temperature above ash melting point, and can not find its

commercial value.

FBC IN-BED TUBES FBC IN-BED TUBES

Maintaining

temperature alltime low of 850-900 °C is because of the remarkably

high co-efficiency of heat transfer in the FBC in-bed tube

submerged inside the fluidizing sand. Compared to the normal

co-efficiency of heat transfer of radiation tube or boiler

convection tube area, co-efficiency of FBC in-bed tubes can

generate steam 5 - 6 times more from the same heating area.

This produces great amount of evaporation in this FBC inbeded

tube area although in relatively small area and the flue

gas entering into the convection boiler tube zone will be

below 600 °C which is almost 200 °C lower than that of other

conventional boilers. |