page 25

| HAMADA BOILER WEB CATALOGUE |

| Compare keungulan |

page 27

page 25 |

|

page 27 |

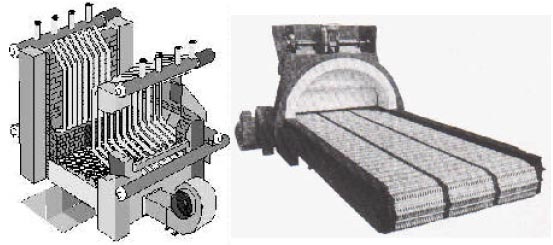

COMPARISON BETWEEN FLUIDIZED BED AND CHAIN STOKER |

|

Hamada Fluidized Bed Combustion |

Travelling Chaingrate |

||

Coal Specification |

Coal Size |

0~10 mm |

15 ~ 50 mm |

Coal Price |

Cheaper ( ± 23 % ) |

More expensive |

|

Ash Content |

No Requirement, can use adaro enviro coal with 1 % ash content |

5 ~ 15 % Chain Grate need at least 5% ash content to protect chain from over heating |

|

Volatile |

No Requirement |

20 ~ 30 % |

|

Combustion System |

Furnace Temperature |

Below 1000 °C |

1300 - 1400 °C |

SOx Problem ? |

With Inject CaCO3 can use coal with high sulfur content |

Must avoid using Coal with high sulfur content |

|

NOx Problem ? |

No, because low temperature at the furnace |

Yes, Because high temperature at the furnace |

|

Ash Melting Problem ? |

No, Because the combustion temperature below ash melting point. |

Yes, Because the combustion temperature is above coal ash melting point ( Indonesian coal is young coal with 1100° ~ 1200° C melting ash temperature ). Melting ash will stick to the chain and Boiler tube, difficult to clean and oiler efficiency become low. |

|

Can Mixed with other Solid |

Yes, Because fuel that still can be burn will remain inside silica sand |

No, because chain grate need fuel with same size and condition |

|

Combustion Efficiency |

Higher, because fuel can stay long inside the silica sand bed until totally finish combustion |

Lower, because bigger coal can not finish burning up to the rear of chain grate and will fall down to ash disposal and fine coal will fly and carried away by the induced draft without burning |

|

page 25 |

Download This |

page 27 |