NEW PYROLOSIS METHOD does not require any pre-process preparation. Process starts from the Fresh Fruit Bunch in its actual form and utilizes PYROLOSIS THERMAL HEAT METHOD.

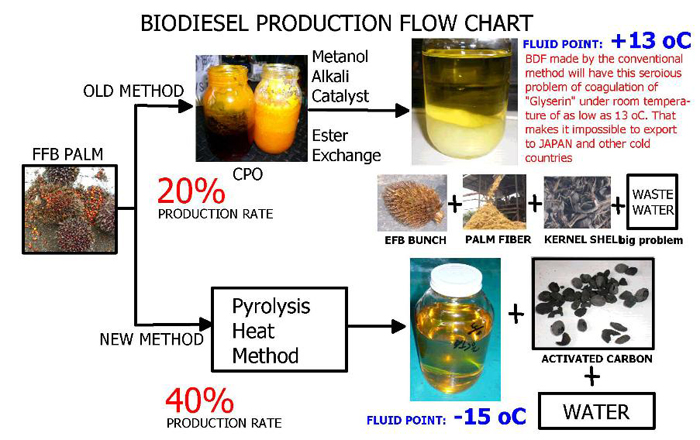

Conventional bio-diesel method uses ESTHER EXCHANGE with Methanol using Alkali Catalyst. Diesel Oil produced by the old conventional method can never be mixed more than 10% against fossil fuel because of the heavy presence of GLYCERIN that will clog the fuel filtering system. Every one liter of fossil fuel produces 2.6 Kg of CO2 when used. Therefore, with mixing ratio of 10%, a liter of fossil-biodiesel mixture still produces 2.35 kilograms of C02. With the new BCF fuel, it could achieve “ZERO” emission by CARBON NEUTRAL.

The conventional palm oil mill that produces Crude Palm Oil or CPO which is the raw materials for bio-diesel production, produces a lot of effluent that requires serious treatment, not to mention its foul odor. It also produces mountains of Empty Fruit Bunch (EFB) which becomes a headache on how to dispose/get rid of it.

The new method BCF system is very environmentally friendly because there’s no effluent waste water coming out of the process. It does not require any treatment of waste water.

In our 2000 kiloliter process plant, it produces 280 liters per hour of Light Oil as by-product which is enough to supply fuel for the 1800 KVA electric generator. Therefore, the electricity requirement is self-sufficient.

Another by-product is the METHYNE GAS. In every 2000 kiloliter plant, it produces 1,050 kilograms of methyne gas at 6000 kilo calories per kilogram, enough to fire the Heating Furnace. Again, it is self-sufficient in fuel for heating.

Another by-product is the carbonized wastes that have its commercial value. Being in carbon form, it does not have foul odor and very easy to handle. |